Parameter Configuration

- levelMinicar

- Energy typegasoline

- engine1.3L 86 horsepower L4

- Gearbox5 block manual

- Long*width*height (mm)3525*1650*1550

- Body structure5 -door and 5 hatchbacks

- Most speed (km/h)145

- Vehicle warrantyTwo years or 60,000 kilometers

- Environmental standardNational IV

- NEDC Comprehensive fuel consumption (L/100km)6.9

Gold Sales

Details

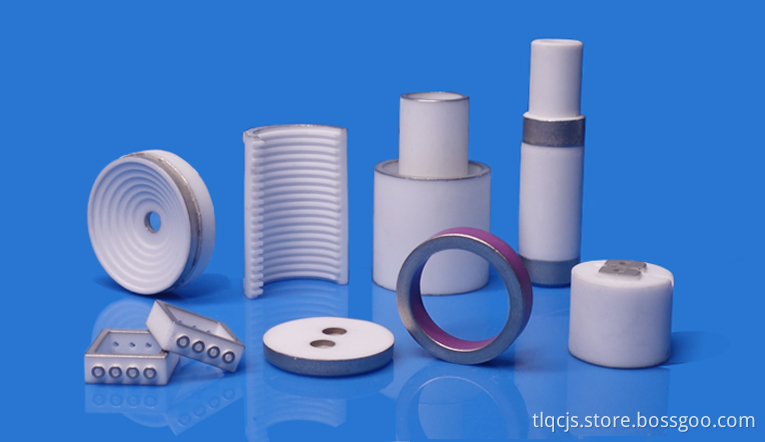

Prime features of metallized ceramic components:

1. Readily accepts Mo/Mn or W metalization for high-temperature brazing of metal to ceramic assemblies

2. Excellent bonding strength over 150 MPa and with ideal leakage rate less than ≤1×10-11 Pa•m3 / s

3. Dense, non-porous ceramic body free of foreign substance and ideal vacuum air tightness

4. High volume resistivity with high insulation strength greater than 18KV/mm (D.C) at least

5. Low coefficient of expansion between 5 to 8 ×10 -6 /℃ under room temperature to 800℃

6. Resists chemical attack which withstand most of strong acid and alkali harsh environment

7. Anti - aging, it's free of rust forever even if the ceramic body expose into air in a long term

8. Fire - resistant & heat - resistance, and high temperature resistance up to 1650 ℃

Specification of metallized ceramic components:

1. Raw material available: alumina (al2o3), zirconia (ZrO2), beryllia oxide (BeO) and aluminum nitride (AlN)

2. Forming methods: Dry pressing, hot pressing, isostatic pressing, ceramic injection molding and so on

3. Types of ceramic components: ceramic tube, ceramic insulator, ceramic substrate, ceramic rings, ceramic cylinder

4. Dimensions capability: Outer diameter can up to be 800 mm, length can over 1000 mm

5. Tolerance : outer diameter can be 0.005 mm, inner diameter can be 0.01 mm, length can be 0.01 mm

6. Other technical parameters: flatness to be 0.005 mm, roundness to be 0.01 mm, parallelism to be 0.01mm

7. Typical metallization : ceramic body + Mo / Mn plating, ceramic body + Mo / Mn + Ni plating

Description of metalized ceramic components:

In order to achieve ceramic to metal joining in these electrical and electronic engineering applications, a metallic layer will be applied on the ceramic base body with high-temperature cured, after that, a protective coating, such as nickel plating covered by the base layer of metallization.

We offer a selection of different grades metalized ceramic components, they are made out of 95%, 99% aluminum oxide ceramics, also zirconium oxide ceramics or beryllia oxide ceramics . These metallized ceramic components are widely used in the electrical and electronic, high vacuum applications, like electron tubes, power grid tubes, vacuum thyristors, gas triode and so on.

Except for metallized ceramics, we manufacturer many other advanced ceramic parts, like ceramic substrate, ceramic tubes, ceramic seals, textile ceramics and so on.

Our strength:

● Offering competitive price with reliable technical ceramic parts ● Support standard to custom made parts

● In-house state -of-the-art types of manufacturing equipment● Within 8 hours response with flexible delivery

● Over 15 years of OEM, ODM manufacturing experience with professional and skillful production & QA team

● Powerful R & D capability and support prototyping of new products to mass serial production of matured products

Car List

- Touring Car Recreational Vehicle Camping Car 2633 $741,837,692

Gold Sales

Touring Car Recreational Vehicle Camping Car 2633

- levelMinicar

- Energy typegasoline

- engine1.3L 86 horsepower L4

- Gearbox5 block manual

- Long*width*height (mm)3525*1650*1550

- Body structure5 -door and 5 hatchbacks

- Most speed (km/h)145

- Vehicle warrantyTwo years or 60,000 kilometers

- Environmental standardNational IV

- NEDC Comprehensive fuel consumption (L/100km)6.9